Coal to ethylene glycol by-product dimethyl carbonate recovery unit

- Production capacity: 15000t/a

- Application of distillation technology: Variable pressure distillation+differential pressure thermal coupling distillation

- Main equipment materials :Carbon Steel、304

- Maximum tower size :DN2400*39650

First, the ability of experimental development

(1) Advanced experimental facilities

The company has a first-class experimental development platform in the industry, with a laboratory area of nearly 800m2, equipped with industry-leading experimental equipment and instruments, such as several sets of distillation columns and crystallizer designed and developed by itself, which can carry out targeted experimental development on specific materials and complete continuous, intermittent, atmospheric, pressurized and vacuum conditional distillation experiments. And equipped with high-precision gas chromatography analyzer, micro-moisture analyzer and other analysis and testing equipment, which can accurately analyze the experimental samples qualitatively and quantitatively. At the same time, it has the ability to simulate different process conditions and environmental parameters, which provides a solid hardware foundation for various chemical experiments and ensures the accuracy and reliability of experimental data.

(2) Professional experimental development team

The company have gathered a group of experienced experimental R&D teams composed of doctors, master students and senior engineers in the industry. Members have profound academic research and practical experience in many fields such as chemical synthesis, distillation separation and catalyst development. Keeping up with the international cutting-edge technology trends, and constantly exploring innovative experimental methods and technological routes, we can quickly formulate scientific and reasonable experimental schemes according to the different needs of customers, carry out experimental research efficiently, solve technical problems for customers and provide customized experimental research and development services.

(3) Rigorous experimental procedures

The company has the ability to carry out distillation separation experiment, reactive distillation experiment and fixed bed reaction experiment, and has carried out more than 100 experiments successively, with rich experience and professional technical team. The laboratory R&D center strictly implements the standardized experimental operation process and quality control system, from the screening and pretreatment of experimental raw materials, to the precise control of the experimental process, to the recording and analysis of experimental data, and every link is strictly checked to ensure the scientific, consistent and repeatable experimental results. By continuously optimizing the experimental process, the experimental efficiency is continuously improved, the research and development cycle is shortened, and the transformation of innovation results is accelerated, which provides a strong guarantee for technological innovation and product upgrading of enterprises.

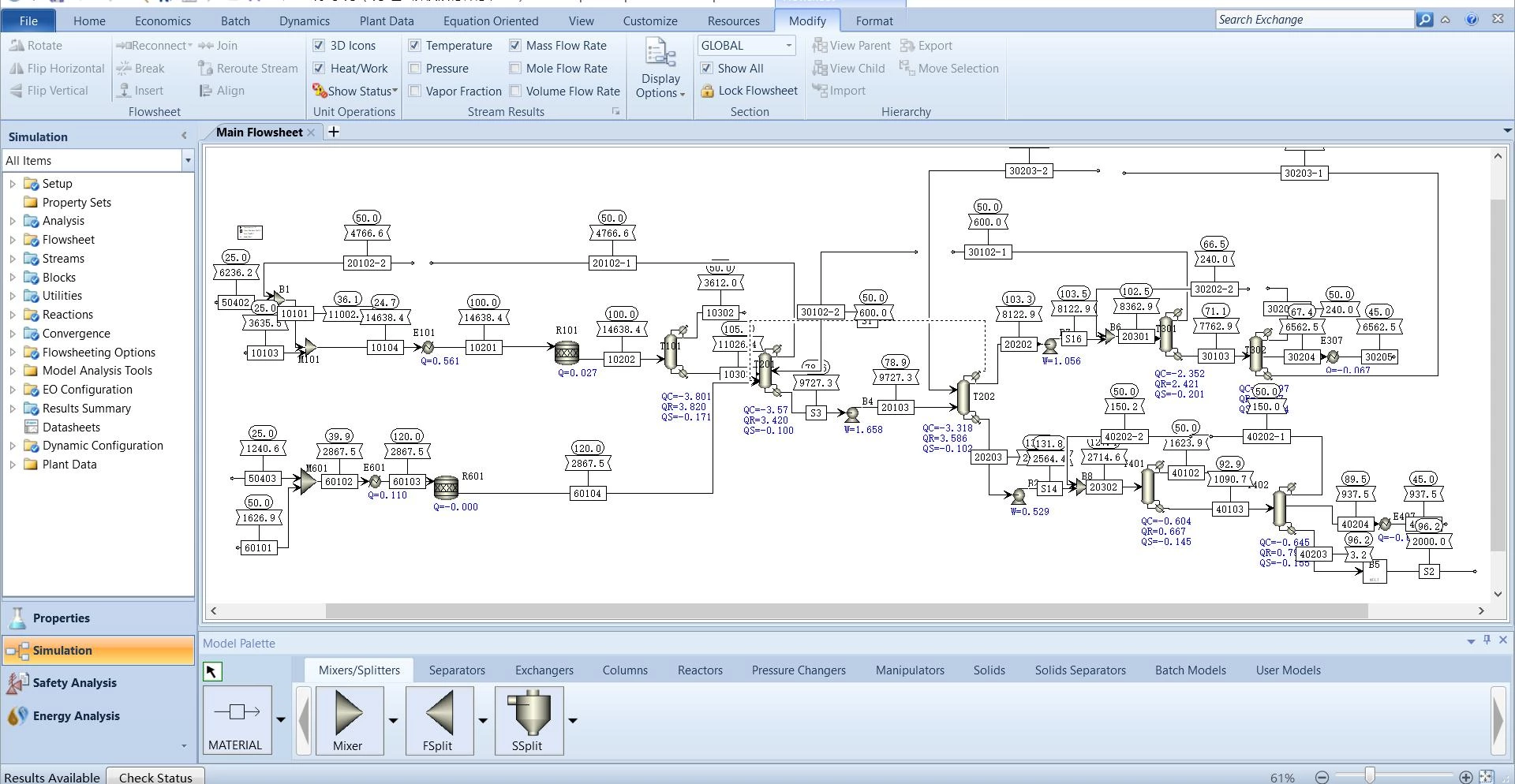

Second, the ability of analog computing

The team has a variety of advanced chemical simulation software application capabilities, such as Aspen Plus, Pro II, HTRI, FRI, COMSOL Multiphysics, etc. These softwares cover many fields, such as chemical process simulation, heat exchanger design calculation, hydraulic calculation of internals, hydrodynamic simulation, etc. They can theoretically model the actual engineering process, compare the simulation results with the actual operation results, and accurately simulate various complex technological processes and physical and chemical phenomena in chemical production.

Three, the core equipment design and processing capacity

The company has the design and processing ability of core equipment-tower internals and packing, especially in the field of packing and tower internals, which can provide efficient, stable and energy-saving equipment technical support for chemical production. Tower internals are the core components of tower equipment, and their performance directly affects the separation efficiency, operational stability and energy consumption of the tower. The internals provided by our company include tray, packing, supporting device, liquid distributor and other types, which are suitable for different tower equipment such as packed tower and plate tower. Relying on advanced calculation tools and professional technical knowledge, the chemical core equipment is designed and calculated in many aspects, such as mechanics, thermodynamics and fluid mechanics. At the same time, according to the chemical process requirements and material characteristics, the internal flow channels and heat and mass transfer elements of the equipment are optimized and calculated to improve the performance and efficiency of the equipment and meet various process requirements in the production process. Our company can provide customers with efficient, stable and energy-saving tower equipment technical support, meet the needs of different chemical processes, and help the efficient chemical production and improve product quality.