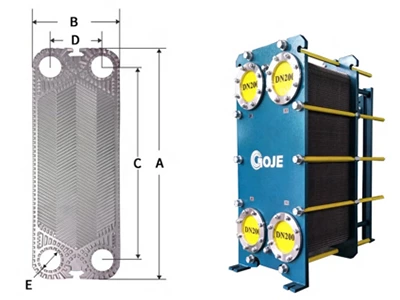

| Model | Singel plate area |

Dimension A*B | Center distance of coner hole C*D |

Coner hole diameter E |

|---|---|---|---|---|

| GJ-A-AK20 | 0.50 | 1215*664 | 931.5*365 | φ210 |

| GJ-A-CLIP10 | 0.63 | 1495*493 | 1324*324 | φ104 |

| GJ-A-CLIP15 | 0.91 | 1746*619 | 1524*400 | φ150 |

| GJ-A-CLIP6 | 0.18 | 997*243 | 859*130 | φ51 |

| GJ-A-CLIP8 | 0.37 | 1244*369 | 1095*220 | φ78 |

| GJ-A-M10M | 0.22 | 871*371 | 719*223 | φ98 |

| GJ-A-M15M | 0.62 | 1498*496 | 1294*298 | φ140 |

| GJ-A-M20M | 0.85 | 1745*620 | 1479*353 | φ205 |

| GJ-A-M3 | 0.03 | 429*125 | 357*60 | φ29 |

| GJ-A-M30 | 1.84 | 2245*995 | 1842*596 | φ328 |

| GJ-A-M6B | 0.15 | 747*248 | 640*140 | φ59 |

| GJ-A-M6M | 0.14 | 747*248 | 640*140 | φ58 |

| GJ-A-M6MW | 0.124 | 748*247 | 640*140 | φ58 |

| GJ-A-MA30W | 1.55 | 2244*995 | 1811*561 | φ330 |

| GJ-A-MK15BW | 0.46 | 1044*298 | 1248*498 | φ140 |

| GJ-A-MX25M/B | 1.48/1.50 | 2246*746 | 1939*439 | φ230 |

| GJ-A-P16 | 0.03 | 427*123 | 357*60 | φ29 |

| GJ-A-P26 | 0.13 | 709*246 | 592*135 | φ70 |

| GJ-A-P36 | 0.36 | 1124*400 | 946*226 | φ120 |

| GJ-A-T20B | 0.90 | 1749*621 | 1478*353 | φ209 |

| GJ-A-T20M | 0.90 | 1745*620 | 1478*353 | φ204 |

| GJ-A-T20P | 0.85 | 1748*622 | 1478*353 | φ210 |

| GJ-A-TL10B | 0.50 | 1499*373 | 1338*218 | φ109.5 |

| GJ-A-TL10P | 0.50 | 1500*375 | 1338*218 | φ105 |

| GJ-A-TL6B | 0.25 | 1149*249 | 1036*140 | φ65 |

| GJ-A-TS20M | 0.29 | 961*621 | 698.5*363 | φ195 |

| GJ-A-TS6M | 0.08 | 509*329 | 380*203 | φ68 |

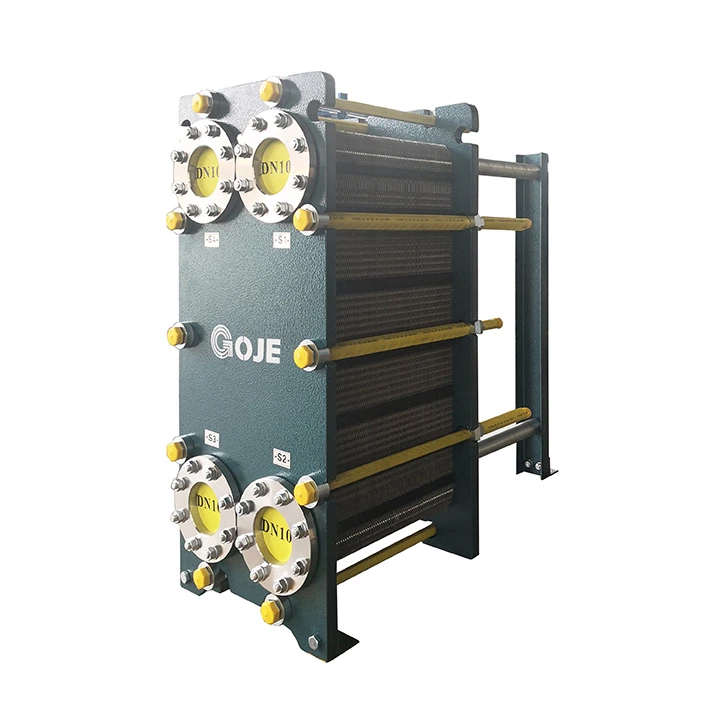

The plate heat exchanger is an advanced solution for liquid-liquid and liquid-steam heat exchange. It delivers high thermal efficiency, compact structure, minimal heat loss, and a heat recovery rate of up to 90%, making it far more efficient than traditional tubular heat exchangers. It is widely applied in metallurgy, petroleum, chemical, food, pharmaceutical, shipping, textile, and papermaking industries.

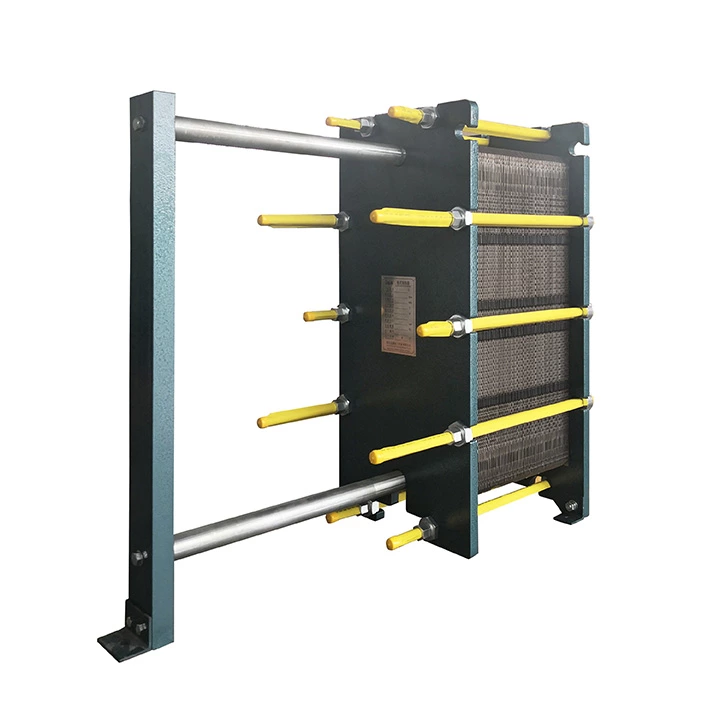

Two structural options are available: the common structure for stable working conditions and the suspension structure for frequent dismantling and cleaning. Both adopt herringbone corrugated plates, sealing gaskets, and robust pressing components to ensure reliable operation.

The corrugated plate surface creates narrow, curved flow channels, forcing the fluid to change velocity direction and generate turbulence. This design breaks boundary layers, enhances heat transfer, reduces energy consumption, and provides strong corrosion resistance with long service life.

The plate heat exchanger is assembled with alternating plates to form mesh channels and separate hot and cold fluids through gaskets. With multiple process combinations—single, multi-process, vapor-liquid exchange, and mixed types—it can be tailored to meet varied industrial requirements.

Preparation stage

Check whether the clamping size meets the requirements of the drawing, and ensure that the material of the plate and gasket is compatible with the medium.

Fill water and exhaust air, install blind plates to seal the pressure testing side.

Pressure testing operation

Use a pressure test pump to slowly increase the pressure to 1.25 times the design pressure (single-sided test) or 1.5 times (whole machine test).

Maintain pressure for 30 minutes and check that all sealing and welding parts have no leakage, which is considered qualified.

Precautions

The pressure should rise evenly to avoid impact.

If the structural limitations prevent liquid filling, pneumatic testing can be used instead.

| Plate Material Characteristics | |

|---|---|

| Material | Application |

| SS304 | Drink water, None Corrosive Liquid, Oils, Fresh Steam etc. |

| SS316L | Well water, river water, closed circulating water and other water with complex components, Dilute sulfuric acid with temperature ≤ 50 ℃ and concentration ≤ 10% etc. |

| Titanium | Liquid that contains chlorine iron, Sea water etc. |

| Titanium Palladium Alloy | Higher temperature and corrosion resistance than titanium. |

| Nickel 20 | It is mainly used for caustic solution (NaOH, Koh, etc.) with high concentration (50% ~ 70%) and high temperature (boiling point). |

| Hastelloy C-276 | It has good corrosion resistance, almost not affected by Cl -, excellent corrosion resistance to various concentrations of sulfuric acid, and is one of the few materials that can be used in hot concentrated sulfuric acid, widely used in organic acids (such as formic acid, acetic acid), high temperature HF acid and a certain concentration of hydrochloric acid (< 40%), phosphoric acid (< 50%); chloride, fluoride. |

| Gasket Material Charactristics | ||

|---|---|---|

| Material | Working Temperature | Working Enviroment |

| NBR | -25~120℃ | Alkane, olefin and other non-polar media, all kinds of mineral oil, animal and vegetable oil, hot water, salt water, etc。 |

| EPDM | -50~170℃ | Superheated water, steam, atmospheric ozone, non petroleum based lubricating oil, weak acid, weak base, ketone alcohol, etc |

| HNBR | -25~150℃ | Crude oil, sulfur-containing oil and organic sulfur compounds, some heat transfer oil, new refrigerant 134a, etc |

| Viton | -25~150℃ | Nonpolar mineral oil, high temperature water vapor, sulfuric acid, chlorine water, phosphate with concentration above 98% |

Headquarters Address: No. 91, Shuanggao Road, Gaochun District, Nanjing,Jiangsu,China

Monday to Friday - 9:00 AM to 6:00 PM

Feel free to fill out our contact form below and our support team will get back to you within 24 hours.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.more details