Freeze crystallization of potassium sulfate, sodium chloride and other substances

- Evaporation rate: 9.5 T/H

- Crystallizer: OSLO continuous freezing crystallizer

- Material: Sodium chloride

Shock-type high-efficiency continuous cooling crystallizer

Technical Principle:

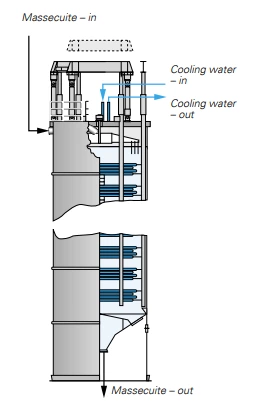

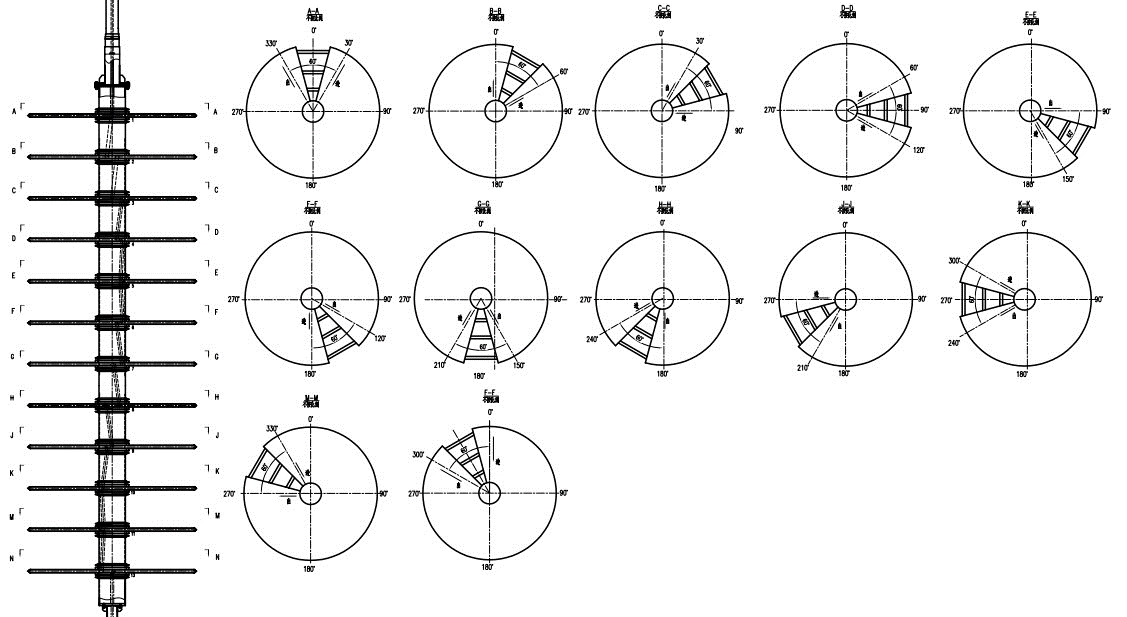

The oscillating cooling crystallizer utilizes the gravity of the crystals in the saturated solution to move from the top of the unit to the bottom of the unit, where the demineralized water flows in coils, countercurrently from the bottom of the unit to the top of the unit, and through specially designed piping to a separate, closed-loop circulating water heat exchanger system. The cooling modules are sequentially assembled in series on a central column and are fully immersed in the solution. The entire cooling unit oscillates vertically at 900 or 950 mm, and the flow rate of the variable piston pumps of the hydraulic system is adjusted to the rate of movement according to the different material characteristics. The concentrated saturated sugar solution is distributed uniformly over the entire crystallizer cross-section by means of a distributor, which, in combination with the symmetrical arrangement of the cooling coils, provides optimized retention times for the best matching of crystallization yield, crystal type, grain distribution and production.

The oscillating cooling crystallizer utilizes the gravity of the crystals in the saturated solution to move from the top of the unit to the bottom of the unit, where the demineralized water flows in coils, countercurrently from the bottom of the unit to the top of the unit, and through specially designed piping to a separate, closed-loop circulating water heat exchanger system. The cooling modules are sequentially assembled in series on a central column and are fully immersed in the solution. The entire cooling unit oscillates vertically at 900 or 950 mm, and the flow rate of the variable piston pumps of the hydraulic system is adjusted to the rate of movement according to the different material characteristics. The concentrated saturated sugar solution is distributed uniformly over the entire crystallizer cross-section by means of a distributor, which, in combination with the symmetrical arrangement of the cooling coils, provides optimized retention times for the best matching of crystallization yield, crystal type, grain distribution and production.

Six hydraulic cylinders are symmetrically mounted on the top cover of the crystallizer and drive the center column via a hairpin frame. The oscillating cooling module also allows for a self-cleaning effect. The bottom discharge agitator and the accompanying single-ended mechanical seal operate continuously during the crystallization process, allowing for a very maintenance-free production process.

By optimizing the process and structure, the new generation of oscillating high-efficiency continuous cooling crystallizer improves the production efficiency of sugar alcohols and can achieve significant energy saving effects.

- The cooling crystallization capacity or cooling area is larger, with a minimum of 2.25㎡/m³ and a maximum of 2.6㎡/m³.

- The cooling coil vibrates to cool the sugar liquid, achieving excellent self-cleaning effect

- In theory, the maximum output of the factory can be achieved by stacking cooling modules

- Through the specially arranged concentric circle and straight tube connection structure, short circuits and material stringing are basically completely eliminated, and the cooling water and sugar liquid are maintained to be uniformly heat transferred and cooled.

- It can be equipped with Gaojie dual-channel dual-logic control super temperature control skid system and software, which will achieve the best effect of cooling crystallization.

Application areas:

Crystallization of glucose monohydrate, fructose, trehalose, psicose, maltitol, isomalt, isomalt, lactic acid and other materials. It has good adaptability to the crystallization of high-viscosity materials.

Technological innovation and progress:

- High-temperature and low-temperature dual-loop cooling system structure designed according to the crystallization cooling curve

- The central tube single column vibrates and rises and falls at a constant speed for stirring;

- Specially designed spiral configuration of cooling coil without short circuit:The cross-section utilization rate is 7.6 times that of other lifting crystallizers, the cross-section material short-circuit area ratio is increased by 63 times, the short-circuit risk is reduced by 98.4%, and the crystallization uniformity of the material can be increased by at least 18.6%;

- The coil design structure has no sudden change points;It eliminates the sudden crystallization phenomenon, i.e. wall-hanging agglomeration defects and the risk of leakage of cooling circulating water.

- The innovatively designed sterile air-sealed isolation structure eliminates the risk of bacterial contamination;

- Six-way adjustable cooling unit guide device eliminates the risk of internal parts rubbing against walls;

- Newly designed hydraulic power system:The six-way synchronous motor and manifold integrated design scheme and high-precision proportional valve control are adopted to eliminate direction change impact and improve synchronization accuracy by 50%. The high-pressure oil pump adopts frequency conversion control mode, saving 40% energy;

- Low energy consumption, high-precision design ideas, temperature difference fitting ±1℃;

- …………

Disc-cooled super crystallizer

Technical Principle:

The disc cooling super crystallizer is vertical. The cooling discs are installed in series on the central axis. They rotate at a constant speed of 1.1rpm under the power of the reducer. All cooling discs are immersed in the materials that need to be pre-crystallized or crystallized in the crystallizer. There are specially designed cooling water channels inside the plate. The crystallizer is equipped with 12 sets of cooling plates. After the cooling water enters the lowermost cooling plate from the bottom central axis, it enters the upper set of cooling plates in sequence through internal pipes. Each set of cooling plates is equivalent to a set of high-efficiency plate heat exchangers with a total thickness of 60mm and a diameter of 3200mm. It cools the sugar liquid step by step to maintain the supersaturation of the material to ensure the continuity of the crystallization process, thus forming the temperature gradient required for crystallization. The pre-crystallized material is injected from the top of the equipment, and contacts the outer surface of the cooling plate for step-by-step heat exchange and cooling. Under the dual effects of the disk scraper and gravity suspension, the crystals and solution decline in a spiral as a whole, and crystallize after reaching the bottom cooling plate. Finish.

By optimizing the process and structure, the new generation of disc-cooled super crystallizer, called super, has obvious performance characteristics compared to other crystallizers:

- 12 sets of cooling plates are connected in series, with a minimum cooling crystallization capacity of 2.6㎡/m³;

- The material and the cooling plate are in full plane contact for heat exchange and cooling, and the radial temperature difference accuracy is 0.5°C;

- The material descending channel of the cooling plate is a reverse spiral descending, and there is no material short circuit or material stringing;

- The flatness of the disk surface is not greater than 3 mm , and adjustable scrapers are installed on the upper and lower disk surfaces to play the dual roles of hanging materials and stirring;

- It can be equipped with Gaojie single-channel dual-logic control super temperature control skid-mounted system and software, which will achieve the best effect of cooling crystallization.

Application areas:

Crystallization of medium and low viscosity materials such as glucose monohydrate, isomaltulose, mannitol, and xylitol.

Technological innovation and progress:

- Single and double loop cooling system structure designed according to crystallization cooling curve

- Equipped with 0-speed start frequency converter and high-torque hard-tooth surface gear reducer, no impact, adjustable speed;

- Specially designed serial spiral configuration of cooling plates without short circuit:

- Specially designed rotary material distributor distributes materials evenly across the crystallizer cross section;

- High-precision bottom bracket mechanism, bottom single-end mechanical seal and bearing integrated installation, eliminating the risk of leakage;

- Low energy consumption, high-precision design ideas, temperature difference fitting ±0.5℃;

- …………