Multiple-Effect Evaporation System

- Location :Korea

- Medium : Waste Oil

- Evaporator Style : Two Effect

- Evaporation Capacity : 2.5T/H

- Production : 99.5% Concerntration

- Main Material : SS304

Technical Feature

Multi-effect evaporation systemMulti-effect evaporation system

Three Evaporators in Series (1st, 2nd, and 3rd Effect): Each effect typically consists of a heating chamber (calandria), a vapor body (evaporation chamber), and a entrainment separator/mist eliminator.

Condenser: Used to condense the secondary vapor generated in the final effect. The condensate can be reused or discharged based on its quality.

Separators: Located after (or integrated at the top of) each effect's vapor body, these devices ensure effective separation of vapor from the concentrated liquor/crystallized salt.

Pump System: Includes feed pumps, circulation pumps (for forced circulation evaporators), and discharge pumps. They are responsible for feeding the raw material, maintaining circulation within effects, and discharging the concentrated solution or slurry from the system.

Auxiliary Systems: Include valves, vacuum pumps, control systems, and instrumentation, which precisely regulate pressure, temperature, flow rate, etc., to ensure stable and efficient system operation.

1.Feeding and 1st Effect Heating: The feed solution is pumped into the heating chamber of the first effect. It is heated to boiling by externally supplied primary steam (live steam), generating secondary vapor.

2.Staged Utilization of Steam: The secondary vapor from the first effect serves as the heating medium for the second effect. Similarly, the secondary vapor from the second effect heats the third effect. Because the operating pressure and boiling point in each subsequent effect are progressively lower (maintained by the vacuum system), the steam is used in stages, significantly reducing fresh steam consumption.

3.Vapor-Liquid Separation and Material Flow: In the vapor body of each effect, the generated vapor is separated from the concentrated liquor. The vapor passes through a mist eliminator/entrainment separator for further purification before entering the next effect's heating chamber. The concentrated liquor flows to the next effect either by the pressure difference between effects or via pumps for further evaporation. The final concentrate or slurry from the last effect is removed by the discharge pump.

4.Condensation and Energy Recovery: The secondary vapor from the third (final) effect is directed to the condenser, where it is fully condensed. The condensate may be reused (e.g., as boiler feed water) or discharged. Throughout this process, the latent heat of the steam is reused multiple times, achieving high energy efficiency.

Mvr evaporation system

MVR (Mechanical Vapor Recompression) Evaporator is an energy-saving technology that reuses the energy of the secondary steam generated by itself, thereby reducing the demand for external energy. The working process of MVR is to compress low-grade steam through a compressor, increase temperature and pressure, increase enthalpy, and then enter a heat exchanger for condensation to fully utilize the latent heat of the steam. Except for start-up, there is no need to generate steam during the entire evaporation process. The secondary steam from the separator is compressed by the compressor, causing the pressure and temperature to increase, and the enthalpy to increase. It is then sent to the heating chamber of the evaporator for use as heating steam to maintain the boiling state of the material, while the heating steam itself condenses into water. In this way, the steam that was originally to be discarded is fully utilized, latent heat is recovered, and thermal efficiency is improved.

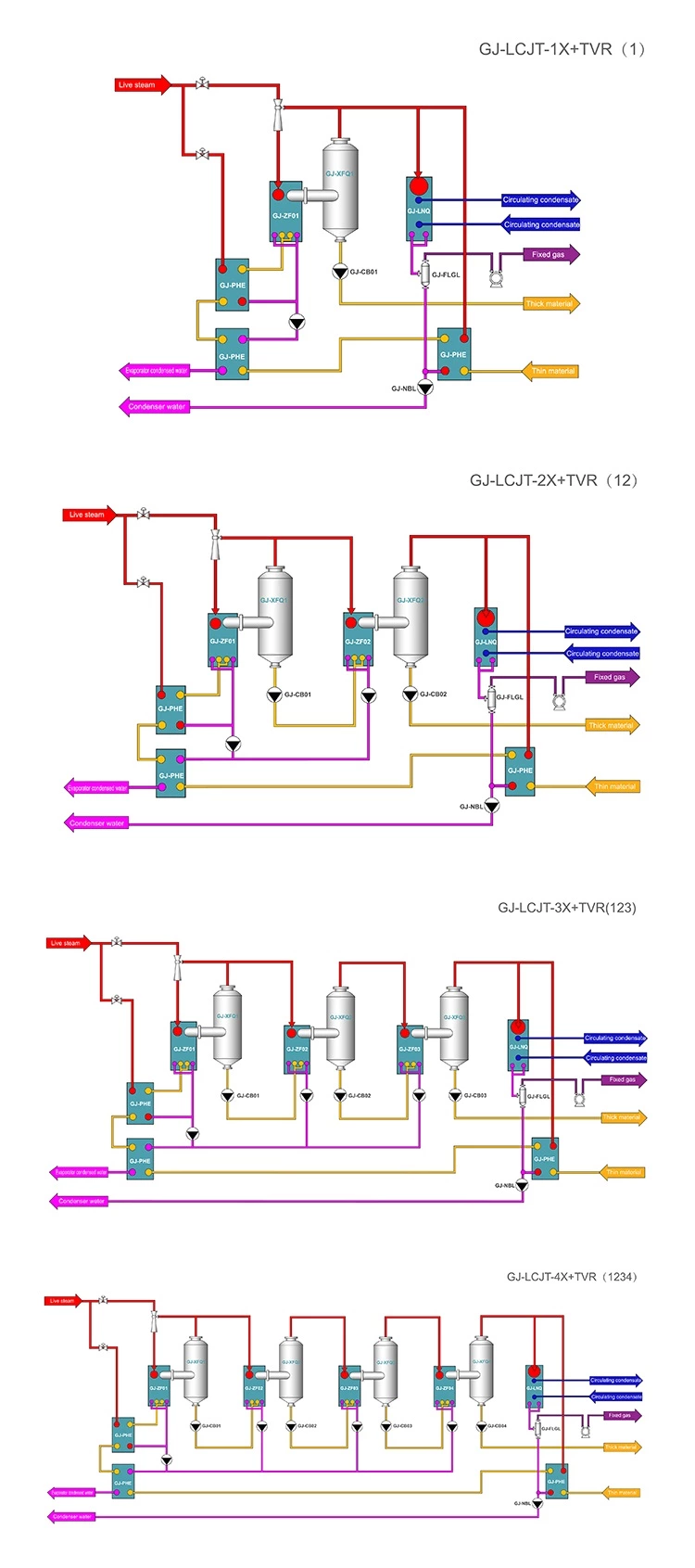

TVR evaporation system

Steam Ejector (Thermal Compressor): The core component of the TVR system, comprising a nozzle, suction chamber, mixing chamber (throat), and diffuser.

Evaporator Body: Typically integrates the heating chamber and evaporation chamber. It receives the medium-pressure mixed vapor from the ejector as the heating medium to boil and evaporate the feed liquid.

Vapor-Liquid Separator / Entrainment Separator: Used to separate the vapor-liquid mixture from the evaporation chamber, ensuring only purified secondary vapor enters the ejector to prevent liquid carryover.

Condenser (Configured as per process requirements): Used to condense excess vapor not entrained by the ejector, maintaining system pressure balance and recovering condensate.

Auxiliary Systems: Include feed pumps, circulation pumps (for forced circulation types), vacuum pumps, control systems (temperature, pressure, level sensors, and valves), and Cleaning-in-Place (CIP) systems.

1.Steam Jet and Entrainment: High-pressure motive steam expands adiabatically through the ejector nozzle, forming a high-velocity jet that creates a vacuum in the suction chamber, thereby entraining the low-pressure secondary vapor from the evaporator.

2.Mixing and Compression: The two vapor streams mix and exchange momentum in the mixing chamber. The kinetic energy of the motive steam is transferred to the secondary vapor, forming a stream of medium-pressure, medium-temperature mixed vapor.

3.Pressure Recovery: The mixed vapor passes through the diffuser, where its velocity decreases, and kinetic energy is converted into pressure energy, raising its pressure to a level suitable for use as an effective heat source.

4.Heat Recovery and Evaporation: The pressurized mixed vapor enters the heating chamber of the evaporator, condenses and releases latent heat to heat the feed liquid. The feed liquid boils, generating new secondary vapor.

5.System Cycle: The generated secondary vapor is drawn into the ejector, starting a new cycle. The concentrated liquid is discharged from the system once the desired concentration is achieved.

Some Classical Processes