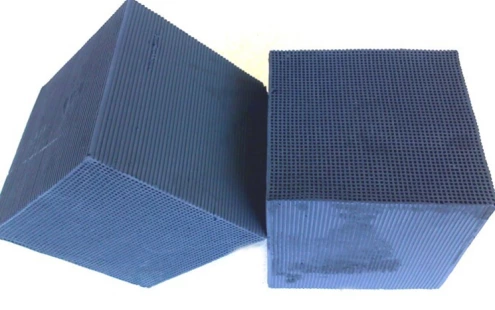

Activated carbon adsorption device

1、Activated carbon adsorption device

After being treated by the pre-treatment device, the waste gas enters the activated carbon adsorption box which is adsorbed on the surface of the activated carbon, then the clean gas is discharged by the rear induced draft fan. Activated carbon is very suitable for adsorbing organic solvents in waste gas. Because it has hydrophobicity and high adsorption efficiency for organic solvents,while other adsorbents have hydrophilicity, they can only adsorb water molecules in the gas and have low adsorption rates for organic solvents.

Utilizing the adsorption characteristics of activated carbon micropores to adsorb organic waste gas is the most effective industrial treatment method. The activated carbon adsorption device adopts a new type of activated carbon, which has a large specific surface area and porosity, strong adsorption capacity, good mechanical strength, chemical stability, and thermal stability, and high purification efficiency.

The organic pollutants in the waste gas are adsorbed on the surface of the activated carbon and seperated by airflow. Gas from the activated carbon adsorption device has reached the emission standard and can be directly discharged. We can design the types according to clients specific requirements such as drawer type, grid filling type, and top loading and bottom unloading type to meet customers’ needs.

2、Definition and element composition of activated carbon

Activated carbon is a black porous solid carbon material. In the early stage, it was made from wood, hard fruit shells, or animal bones by carbonization and activation, and later use coal through pulverization, molding, or granular coal by carbonization and activation.The main component is carbon with few elements of oxygen, hydrogen, carbon with low packing density and large specific surface area. Because its irregular arrangement of microcrystalline carbon and fine pores between cross connections, which can cause carbon tissue defects during activation. The specific surface area of ordinary activated carbon ranges from 500 to 1700 m2/g. It is a widely used industrial adsorbent and has strong adsorption performance.

Activated carbon is made up of 80%-90% carbon which is the reason why activated carbon is a hydrophobic adsorbent. In addition to carbon elements, activated carbon also contains two types of admixtures: one is chemical elements, mainly oxygen and hydrogen, which are left in the carbon due to incomplete carbonization, or during the activation process, the external non carbon element chemically combine with the surface of the activated carbon, such as when activated by water vapor, the surface of the activated carbon is oxidized; Another type of admixture is ash, which is the inorganic part of activated carbon. Experts in activated carbon can see that it also contains a small amount of Cl.

3、Working principle of activated carbon

Activated carbon is a hydrophobic adsorbent made from carbon-based materials through high temperature carbonization and activation. It contains a large number of micropores and has a huge specific surface area, which can effectively remove color,odor and most organic pollutants and some inorganic substances like some toxic heavy metals. The factors that affect the adsorption of activated carbon including: the characteristics of activated carbon,the characteristics and concentration of the adsorbed substance, pH value of wastewater,suspended solid content,contact system and operation mode, etc. Activated carbon adsorption is the most important and effective treatment technology in handling urban sewage, which has been widely applied.

Activated carbon can effectively adsorb chlorinated hydrocarbons, organic phosphorus, and carbamate insecticides, as well as phenyl ether, n-nitrochlorobenzene, naphthalene, ethylene, xylenol, phenol, DDT, aldehydes, alkylbenzenesulfonic acid, and many esters and aromatic compounds. There are also some organic substances that are not adsorbed by activated carbon in the secondary effluent, such as intermediate degradation substances of proteins, which are more difficult to be adsorbed than the original organic substances. The removal ability for THMS is relatively low, only reaching 23-60%. The combination of activated carbon adsorption with other treatment methods significantly prolongs the adsorption cycle, reduces the dosage, and greatly improves the treatment effect and scope. New methods like Ozone-activated carbon method, coagulation adsorption activated carbon method, Habberer process, activated carbon diatomaceous earth method.

Activated carbon adsorption technology was born in the First World War.Soldiers wore gas masks to protect themselves from toxic gas.In 2003,SARS outbroken, doctors and nurses all used activated carbon masks to against. These are enough to prove that activated carbon adsorption technology has become the most mature technology for harmful gas adsorption and treatment. Activated carbon is a porous carbon containing substance with a well-developed pore structure that gives it a large surface area, making it easy to fully contact with toxic and harmful gases in the air. The strong adsorption field around the activated carbon pores will immediately suck toxic gas molecules into the pores.

Activated carbon adsorption technology utilizes the principle of absorbing odors and harmful gases from carbon, and has been used for a long time. Therefore, it is mature, stable, cost-effective, non-toxic, and has no side effects. It has good adsorption effects on hydrogen sulfide, ammonia, formaldehyde, benzene, and volatile organic compounds (VOCs), and will not produce secondary pollution.

4、Classification of activated carbon

(1)Coconut shell charcoal - It is made from high-quality coconut shells from Hainan, Southeast Asia, and other regions. The raw materials are screened, steam carbonized, refined, and then processed through a series of processes such as impurity removal, activation and screening. It is a black granular material with developed pore structure, high adsorption capacity, high strength, stable chemical properties, and durability. Widely used in metallurgy and chemical industry, petroleum and electricity, food and beverage, drinking water, purified water, industrial water deep purification, and the extraction of precious metals, it has the effects of decolorization, deodorization, adsorption and turbidity removal, and has better compatibility with zeolite and molecular sieve, which is deeply welcomed by users.

(2)Fruit shell charcoal - Fruit shell activated carbon is mainly made from fruit shells and wood chips, which are carbonized, activated, and refined. It has the characteristics of large specific surface area, high strength, uniform particle size, well-developed pore structure, and strong adsorption performance. And it can effectively adsorb free chlorine, phenol, sulfur, oil, resin, pesticide residues and other organic pollutants in water, as well as the recovery of organic solvents. Suitable for pharmaceutical, petrochemical, sugar making, beverage, and alcohol purification industries, decolorization, refinement and purification of organic solvents,and sewage treatment etc.

(3)Wooden charcoal – It is made from high-quality wood, which is refined through high-temperature carbonization, activation, and various processes. It has large specific surface area, high activity, well-developed micropores, strong decolorization ability, and large pore structure that can adsorb colors and impurities in liquid. Mainly used for decolorization of various purposes such as food, alcohol, oils, beverages, dyes, chemicals, tap water purification, sewage treatment, COD reduction, pharmaceutical activated carbon, etc.

(4)Columnar charcoal - ① Characteristics: Mading from high-quality wood chips, coconut shells, after crushing, mixing, extrusion, forming, drying, carbonization and activation. ② Originality: Adopting proprietary technology of non bonded formed activated carbon. It changes the method of forming with traditional binders such as coal tar and starch. Without binder components and relies entirely on the affinity between carbon molecules and the special properties of the raw material itself. Effectively avoiding carbon pore blockage and fully utilizing the adsorption function of carbon pores.③Advanced nature: As high-quality wood chips and coconut shells are used as raw materials, the columnar activated carbon produced has lower ash content, less impurities, better gas adsorption value and CTC than the traditional coal columnar carbon. The pore size distribution of the product is reasonable, achieving maximum adsorption and desorption, greatly improving the service life (average 2-3 years), which is 1.4 times than ordinary coal based carbon. With columnar and spherical specification. ④ Applicability: Gas phase adsorption, organic solvent recovery (benzene gas toluene, xylene, acetone recovery in the acetate fiber industry), impurity and harmful gas removal and waste gas recovery, excess gasoline recovery in refineries, gas stations, and oil depots.

(5)Coal based carbon - Coal based columnar activated carbon is made from high-quality anthracite coal with a black cylindrical particle appearance; It has reasonable pore structure, good adsorption performance, high mechanical strength, easy to repeatedly regenerate, and low cost. Used for the purification of toxic gases, waste gas treatment, industrial and domestic water purification, solvent recovery and other aspects.

5、The application field and scope of activated carbon

Applied in industries such as chemical, oil, petrochemicals, pharmaceuticals, pesticides, automotive components, coatings, electrical, electronic components, printing, electroplating, canned vehicles, rubber, photosensitive materials, fibers, plastics, artificial leather, dry cleaning, etc. Applicable organic matter types:

1) Hydrocarbons: benzene, toluene, n-hexane, naphtha, cyclohexane, methylcyclohexane, dioxane, diluent, gasoline, etc;

2) Alkenes: trichloroethylene, perchloroethylene, trichloroethane, dichloromethane, trichlorobenzene, dichloroethane, trichloromethane, carbon tetrachloride, fluorocarbons, etc;

3) Aldehydes and ketones: formaldehyde, furfural, acetone, MEK (methyl ethyl ketone), MIBK (methyl isobutyl ketone), cyclohexanone, etc;

4) Esters: ethyl acetate, butyl acetate, ethyl oleate, etc;

5) Ethers: methyl ether, methyl ether, THF (tetrahydrofuran), etc;

6) Alcohols: methanol, ethanol, isopropanol, n-butanol, isobutanol, etc;

7) Polymeric monomers: vinyl chloride, acrylic acid, styrene, vinyl acetate, etc;

8) Amides: dimethyl formamide (DMF), dimethyl acetamide, etc;

6、Technical parameters of activated carbon

1) The temperature of waste gas should not exceed 40 degrees;

2) Adsorption saturation 26%-33%;

3) The specific surface area ranges from 500 to 1700m2/g;

4) Filling density 0.45-0.55g/cm;

5) Moisture ≤ 10%;

6) After the activated carbon adsorption is saturated, we need to heat exhaust gas to desorb the saturated activated carbon. The heating temperature is generally not higher than 120 ℃; When steam is used for desorption of saturated activated carbon, the temperature can be higher than 120 ℃, but does not exceed 200 ℃. Specific adjustments need to be made based on the characteristics of the exhaust gas;

7) Each kilogram of activated carbon adsorbs 0.15-0.3 kg of organic waste gas..

7、Application field

Activated carbon adsorption devices play an important role in multiple industrial fields and environmental governance due to their efficient adsorption performance.

- water treatment field

Activated carbon adsorption equipment can effectively remove pollutants such as organic matter, heavy metal ions, suspended solids, and algae from water, significantly improving water quality. In drinking water treatment, it can remove harmful substances such as chlorine and organic matter, ensuring the safety of drinking water.

- Air purification and exhaust gas treatment

This device is widely used to remove harmful gases such as formaldehyde, benzene, ammonia from the air, as well as pollutants from industrial waste gas. Specially suitable for processing high air volume and low concentration organic waste gases (such as benzene, toluene, xylene, alcohols, esters, etc.), commonly used in spray painting and coating workshops in industries such as electronics, chemical, light industry, rubber, machinery, automobiles, and petroleum. In addition, it is also used in indoor decoration, automobile exhaust treatment, and gas station oil and gas recovery scenarios.

- food industry

In food processing, activated carbon adsorption equipment is used for decolorization, deodorization, removal of impurities, and improvement of product quality and taste. It is commonly used in production processes such as sugar making, brewing, and beverages.

- Pharmaceutical and Biological Products

This device is used for the extraction and purification of drugs and biological products, such as the separation of biomolecules such as proteins and enzymes, due to its excellent adsorption performance and biocompatibility.

- chemical engineering field

In industries such as petrochemicals, rubber, and pesticides, activated carbon adsorption devices are used for the separation and purification of chemical products, as well as the treatment of waste gas and wastewater, effectively removing harmful substances.

- Metallurgical industry

Activated carbon plays a key role in gold extraction (such as carbon slurry method and carbon leaching method), non-ferrous metal refining (such as solution purification of copper, nickel, and cobalt), and steel smelting (as a reducing agent and desulfurizer), which can improve metal recovery rate and product purity.

- Other fields

It also includes industries such as packaging printing, leather making, and ultra-fine fiber (synthetic leather), which are used to purify organic substances in exhaust gases, achieve resource recovery, and control pollution.