Low temperature evaporator

Product Introduction:

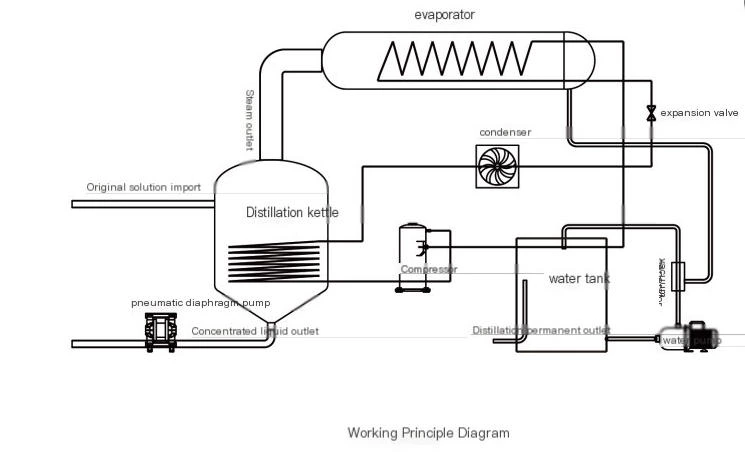

The main function is to reduce the boiling point under the effect of vacuum and negative pressure, so that the original liquid will boil and evaporate at more than 30 degrees after being heated. The evaporated steam will be condensed into liquid water through the condensation system and discharged through the drain tank. The maximum water yield can reach 95% according to the different concentration and reduction of water quality specific gravity. With this equipment, the cost of waste liquid treatment can be greatly reduced. The equipment occupies a small area, is convenient to move, and has a high degree of automation. It does not need external steam sources and peripheral cooling water, but only needs to provide electricity and a small amount of compressed air.

Main features:

- Energy saving: evaporation under vacuum environment (about - 94~- 97Kpa), the energy consumption ratio of ordinary air conditioners is 1:3.5. This equipment uses the heat source of the compressor for heating and uses the cooling capacity for condensation. The energy consumption ratio is equivalent to 1:7, that is, for every 1KW of electric energy used, 7KW of energy is output.

- Power supply: 380V/50Hz/three-phase five wire system.

- The heat exchanger is made of stainless steel 316L and can be equipped with titanium alloy or others.

- The kettle body is made of stainless steel 304 or 316L, and can be equipped with internal spray Teflon.

- The system can operate fully automatically, with human machine interface monitoring, automatio cleaning and defoaming functions.

- Environmental requirements: spacious, ventilated, rain proof, room temperature 10-35 * C, convenient water inlet and outlet.

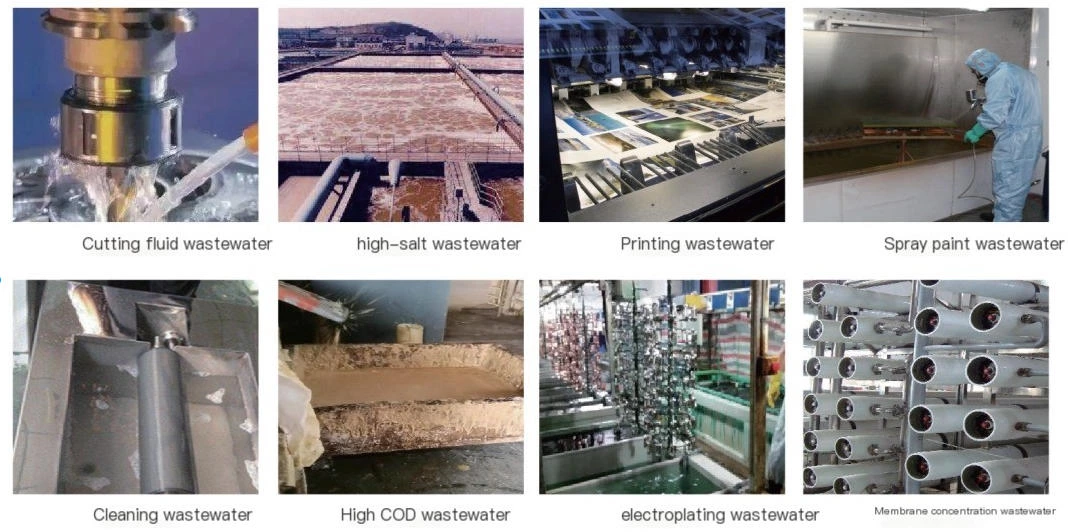

Application field: