FC crystallization evaporator comparison of different circulation methods

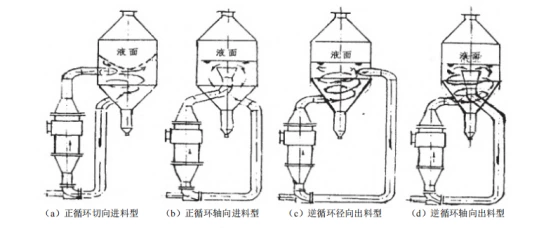

According to many engineering cases, it is found that the growth of crystal nuclei and the growth of crystals in the process of evaporation of forced circulation do not reach the form, therefore, the feeding method, flow direction and the addition of salt legs of different raw liquids in the forced have been improved. The following forms are common and analyzed.

Class a forced evaporation in the ordinary evaporator on the basis of salt legs, the process is easy to produce, evaporation intensity, granular material falls into the salt legs; the evaporator feed method for tangential feeding, resulting in solid-liquid segregation or separation, crystals grow up deviate from the supersaturated solution area, with the cylinder down, resulting in particle size of the particles is small; when the circulation volume increases, the flow rate becomes larger, resulting in material thermal short circuit, the loss of temperature difference increases; At the same time, the gas-liquid interface is easy to crystallize scaling, falling to the heating pipe to plug the heating pipe, need to clean up.

The advantage of class b forced evaporation is that the heated material liquid is entering from the center tube of evaporation chamber and conveying the liquid level, the evaporation intensity of liquid surface evaporation in the center of evaporation chamber is large, and the evaporation intensity near the cylinder wall is relatively small, and it is not easy for the cylinder wall to crystallize the salt bar; the material liquid in the evaporation chamber flows in the same axial direction as the crystals and the solid-liquid mixing is uniform. However, due to the heated material liquid only in the evaporation of the solution within the uppermost part of the vaporization, resulting in the maximum degree of supersaturation of the solution here, while the density of the crystal slurry is small and the crystal particle size is small, is not conducive to the rapid elimination of supersaturation, and at the same time the crystal in the evaporation chamber of the residence time is short, it is difficult to obtain larger crystals; some of the large crystals have been molded circulating tube, broken by the forced circulation pump impeller, resulting in the generation of the second crystal nucleus.

Class c forced evaporation overcomes the shortcomings of positive cycle axial feed forced evaporation, and long production cycle, crystal particle size. However, its form of forced circulation evaporation in order to reduce the fluid resistance in the circulation tube, resulting in circulation tube diameter becomes large, and the circulation tube connected with the evaporation chamber and the upper liquid surface distance is short, easy to foam inhalation, resulting in serious axial pump vapor corrosion.

Class d forced evaporation is an improved version of class c, the discharge pipe mouth oil vertical to horizontal, the mouth of the pipe can be maximized close to the upper liquid surface, hot liquid short circuit phenomenon has been improved, and the circulating pipe inhalation of air bubbles defects have been alleviated.

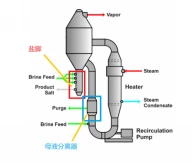

In order to improve the quality of the product salt and reduce the content of impurities, a mother liquor separator is added to the lower recirculation pipe to quantitatively discharge the concentrated mother liquor and reduce the content of impurities in the salt.