Selection of flow meters for special operating conditions

1. Selection of slurry flow measurement

A list of various flow meters for applications involving slurries containing particulate fibers:

| type | Subcategories | Measurement accuracy | Properties suitable for slurries containing particulate fibers | Applicable restrictions |

| Differential pressure flow meter | Bends, wedges, and rings | Depending on the subdivision type, segmental orifice plates and eccentric orifice plates offer more stable accuracy when the solid phase is relatively small. | It has strong structural adaptability; the bends and wedges do not have complex throttling structures and are not prone to particle accumulation. | Measurement errors increase with high solid content, and Venturi tubes and similar devices can only be used in specific slurry measurement scenarios. |

| Electromagnetic flowmeter | Standard type (compatible with conductive paste) Special type (ceramic lining and other wear-resistant types) | ±0.2% - ±1.0% | The measurement is stable and unaffected by slurry viscosity and density. There is no risk of blockage in straight pipe sections, making it suitable for scenarios such as coal-water slurry with a coal powder content of up to 65%. | This method is only applicable to conductive slurries; slurries containing ferromagnetic particles will interfere with the magnetic field and affect the measurement. |

| Doppler ultrasonic flow meter | External clamp-on probe | ±1% - ±5% | Installation without cutting off pipes, no contact with grout, and compatible with non-conductive grout containing particles. | The measurement accuracy is low, and it is easily affected by the uneven distribution of air bubbles and particles in the slurry, resulting in easily disordered signals. |

| Vortex flow meter | Standard industrial model | Under normal operating conditions, ±0.5% - ±1.5% | It can only measure slurries containing a small amount of powdery solid phase; the measurement principle is simple and the cost is moderate. | High solid content or the presence of fibers can generate noise, making normal measurement impossible. |

| Target flow meter | Strain gauge target flow meter | ±1% - ±2% | With no narrow channels and strong anti-clogging ability, it is suitable for slurries containing particles such as heavy oil and residual oil containing pulverized coal. | When dealing with high-concentration coarse fiber slurry, the target sheet is prone to wear and requires regular maintenance. |

| Coriolis mass flow meter | Straight tube type measuring tube | High precision, typically with an error of < ±0.5%. | There is international experience in slurry measurement applications; it can directly measure mass flow rate and is less affected by slurry conditions. | Limited domestic application experience, high equipment and maintenance costs, and poor compatibility with large-diameter pipelines. |

Based on the current usage of flow meters in China and the measurement performance of various flow meters, electromagnetic flow meters are the preferred choice for measuring slurry flow. Other flow meters should only be selected if the slurry being measured is non-conductive or contains ferromagnetic particles, or if the pipeline system cannot be interrupted to connect to the flow sensor. Reports indicate that years of experience measuring the flow of coal-water slurry with a coal powder content as high as 65% suggest that electromagnetic flow meters are still the best option.

Differential pressure flow meters can be used to measure the differential pressure of slurries. In addition to bends, wedges, and annular tubes, they can also be used when the solid phase is small. Segmental orifice plates and eccentric orifice plates can also be used. Venturi tubes have also been used for measurement.

Doppler ultrasonic flow meters can measure flow without cutting off the pipe by clamping an ultrasonic transducer (probe) on the outside of the pipe, but the measurement accuracy is not high.

Vortex flow meters can only measure materials containing small amounts of powdery solids. They cannot be used if the solid content is high or if the material is fibrous, as this will generate noise.

Target flow meters are used for liquids containing pulverized coal, such as heavy oil or residual oil, and employ strain gauge target flow meters.

Coriolis mass flow meters have been used in slurry measurement abroad, and their straight-tube measuring tubes are generally preferred, but there is not much experience with their application in China.

2. Selection of Large Flow Rate Liquid Measurement

The term "large flow rate" here does not refer to the "relatively large flow rate" when the flow velocity is high for a certain pipe diameter, but rather to the large flow rate in absolute terms. Since the flow velocity of liquids transported in pipelines is within a certain range, the commonly used economical flow velocity for low-viscosity liquids is 1~3m/s. Therefore, the "large flow rate" measurement mentioned here refers to the flow rate measurement of large pipelines.

Generally speaking, flow meters with pipe diameters below DN300 are called small and medium diameter flow meters, those with diameters between DN300 and DN400 are called large diameter flow meters, and those with diameters above DN1200 are called extra-large diameter flow meters. Extra-large diameter flow meters are typically used for measuring the flow of water, but also for petroleum products. Common types of large diameter flow meters include differential pressure flow meters, electromagnetic flow meters, ultrasonic flow meters, and insertion flow meters. For diameters between DN300 and DN500, there are also volumetric flow meters and turbine flow meters.

(1) Installation conditions

The installation conditions mainly depend on whether the measurement method allows for cutting off the flow in the pipe and suspending operation, whether it allows for drilling holes in the pipe, and whether it allows for cutting off the flow in the pipe to install the flow sensor.

If it is permissible to install a flow sensor with the flow cut off, electromagnetic flow meters, ultrasonic flow meters with a measuring pipe section, volumetric flow meters, and turbine flow meters can be selected.

If drilling into the pipe is permitted, external transducer ultrasonic flow meters and insertion flow meters can be selected.

If none of the above requirements are allowed, then the only option is an externally mounted ultrasonic flow meter with a transducer.

(2) Measurement accuracy requirements

For trade transactions requiring high measurement accuracy, and for non-conductive liquids, ultrasonic flow meters with measuring pipe sections, multi-channel ultrasonic flow meters, volumetric flow meters, and turbine flow meters can be selected. For conductive liquids, electromagnetic flow meters can also be selected.

For applications requiring controlled proportions and lower measurement accuracy, differential pressure venturi tube or clamp-on transducer ultrasonic flow meters can be selected. For applications requiring even lower measurement accuracy, insertion flow meters can be chosen.

(3) Pressure loss (pumping energy consumption cost)

Pumping energy costs account for a significant proportion of the operating costs of flow measurement systems, particularly for high-flow-rate measurements. For example, differential pressure venturi meters, volumetric flow meters, and turbine flow meters have relatively high pressure losses. Insertion flow meters have lower pressure losses, while electromagnetic flow meters have no pressure loss.

3. Selection of Steam Flow Measurement

Steam flow measurement is technically divided into two categories: one is superheated steam and high-dryness-parts-content (dryness parts x=0.9 or higher) saturated steam, and the other is low-dryness-parts-content saturated steam. The former can be treated as a single-phase fluid, while the latter is a two-phase flow. Since all current flow meters are only suitable for single-phase fluids, further in-depth research is needed on low-dryness-parts-content saturated steam.

(1) Flow measurement of superheated steam and high dryness saturated steam

Commonly used flow meters include: throttling differential pressure flow meters, which remain the primary instrument for measuring steam flow. To meet evolving needs, technological advancements have been made. For example, the throttling device, differential pressure transmitter, and three-valve manifold are integrated into a single unit, creating an integrated throttling flow meter. This design overcomes the vulnerability of differential pressure signal pipelines to failure. Another approach involves using stationary throttling elements, replacing standard orifice plates with standard nozzles. Compared to orifice plates, nozzles offer a more stable discharge coefficient, unaffected by blunted edges, and exhibit lower pressure loss—typically 30% to 50% of that of orifice plates at the same flow rate and value.

Vortex flow meters are well-established for measuring medium temperatures, i.e., below 200℃, and are commonly used for steam measurement. However, it is important to note that low-dryness media will cause the instrument coefficient to deviate from the detected value, increasing measurement error.

Averaging pitot tube flow meters and split-flow rotary vane flow meters are still suitable for internal management and distribution where accuracy requirements are not too high, because they are relatively inexpensive and simple to use, and are suitable for measuring small to medium flow rates of steam.

For target flow meters, the electric and pneumatic target flow transmitters developed in China in the 1970s are the measuring instruments for electric and pneumatic unit combination instruments. Because the force converter at that time directly adopted the force balancing mechanism of the differential pressure transmitter, it brought many shortcomings inherent in the force balancing mechanism itself. For example, low measurement accuracy, zero drift, poor reliability and stability of the lever mechanism, etc. Therefore, the original JJG461-1986 "Target Flow Transmitter" specification, formulated in 1986, is now 25 years old. Since electric and pneumatic target flow transmitters are no longer widely produced or used, the original specification is no longer suitable, and a new target flow meter specification has been revised. The structure of a target flow meter consists of a measuring tube, a target plate, a force sensor, and a signal processing unit. The force sensor is a strain gauge type sensor, and the signal processing display can be directly read on-site or output a standard signal. The force sensor consists of a cylindrical elastic body and a strain gauge, and can be either internally or externally mounted. When an elastic body deforms under force, it disrupts the balance of the Wheatstone bridge composed of strain gauges, generating an electrical signal that is proportional to the square of the flow rate. Its working principle involves placing a target plate perpendicular to the flow direction in a straight pipe section with a constant cross-section. As the fluid flows around the target plate, it experiences a thrust, the magnitude of which is proportional to the kinetic energy of the fluid and the area of the target plate. Within a certain Reynolds number range, the flow rate through the flowmeter is proportional to the force acting on the target plate. The force on the target plate is detected by a force sensor.

Taking a circular target plate as an example, the basic formula for flow rate calculation is:

Mass flow rate calculation formula

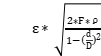

Qm=K*

Corrected formula considering compressible fluids

When measuring compressible fluids (such as slurries or steam containing small amounts of gas), a correction for the flow expansion coefficient needs to be introduced, and the formula is adjusted as follows:

Qm=K*

| parameter | Parameter name | unit | Meaning and Notes |

| mass flow | kg/s | The mass of fluid passing through the pipe per unit time is the core measurement result of the target flow meter. | |

| Volumetric flow rate | m³/s | The volume of fluid passing through a pipe per unit time can be derived by dividing the mass flow rate by the fluid density. | |

| Flow coefficient | Dimensionless | The shape of the target plate (circular in this case), the inner diameter of the measuring tube, and the fluid flow state (Reynolds number) all affect the accuracy and require experimental calibration. | |

| Coefficient of expansion of the stream | Dimensionless |

The effect of fluid compressibility on measurement: - Incompressible fluids (such as most slurries and water): - Compressible fluids (such as slurries containing air bubbles and gases): and the larger the pressure difference, the smaller the value. |

|

| Measuring tube inner diameter | m | The actual inner diameter of the pipe at the installation location of the target-type flow meter (the pipe wall thickness should be deducted, and the actual measured value should be used as the standard). | |

| target diameter | m | This refers to the actual diameter of the circular target plate, typically ranging from 0.2 to 0.8. The appropriate target diameter ratio should be selected based on the slurry concentration (particle content) (a smaller target diameter ratio should be used for high-concentration slurries to avoid clogging). | |

| fluid density | kg/m³ | For slurries containing particulate fibers, the overall density of the slurry (including the mixed density of solid particles and liquid medium) should be used, rather than the density of a single liquid phase. | |

| Force on the target | N | The force generated by the slurry flow impacting the circular target plate is the original physical quantity for flow measurement and directly determines the subsequent signal conversion result. |

The force applied to the target plate is converted into a current signal (4 ~ 20) mA or a gas pressure signal (20 ~ 100 kPa) by a force converter. The relationship between the output signal and the flow rate can be determined according to the above formula.

Due to its novel structure and measurement principle, the strain gauge target flow meter has a promising future in steam measurement and is suitable for measuring small to medium flow rates of steam.

(2) Flow measurement of low dryness saturated steam

Typical industrial boilers produce saturated steam with a high dryness fraction (above 0.95) at the outlet. However, during long-distance transport, factors such as poor insulation or imbalances caused by intermittent steam use lead to a continuous decrease in dryness, eventually turning the steam into a wet steam with high water content, thus becoming a two-phase fluid (gas and water). The flow characteristics of this two-phase fluid are fundamentally different from those of single-phase flow. Flow meter coefficients or discharge coefficients measured in single-phase flow cannot be used for two-phase flow measurements. For example, the discharge coefficient in a two-phase flow test using an orifice flow meter must be corrected for dryness. Therefore, dryness is a crucial parameter to measure in the flow measurement of low-dryness saturated steam. Unfortunately, a mature dryness meter is currently unavailable. Furthermore, the dryness correction of instrument coefficients for other types of flow meters has not been thoroughly investigated. Only by solving this problem can the flow rate of low-dryness saturated steam be measured.