Zinc sulfate monohydrate MVR evaporation crystallization

1.1Zinc sulfate

Zinc sulfate is an inorganic compound with the chemical formula ZnSO₄ , appearing as colorless or white crystals, granules, or powder. It is primarily used as a raw material for producing pigments such as lithopone, zinc barium white, and other zinc compounds. It is also used as a nutrient for zinc-deficient animals, a feed additive in livestock farming, a zinc fertilizer (micronutrient fertilizer) for crops, an important material for synthetic fibers, an electrolyte in the electrolytic production of metallic zinc, a mordant in the textile industry, an emetic in medicine, an astringent, a fungicide, and a preservative for wood and leather.

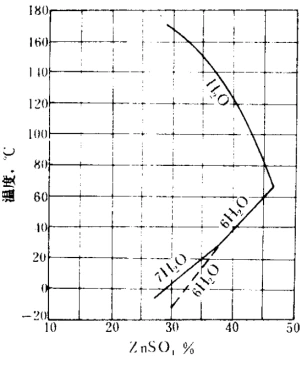

Zinc sulfate solubility curve:

1.2MVR evaporation process

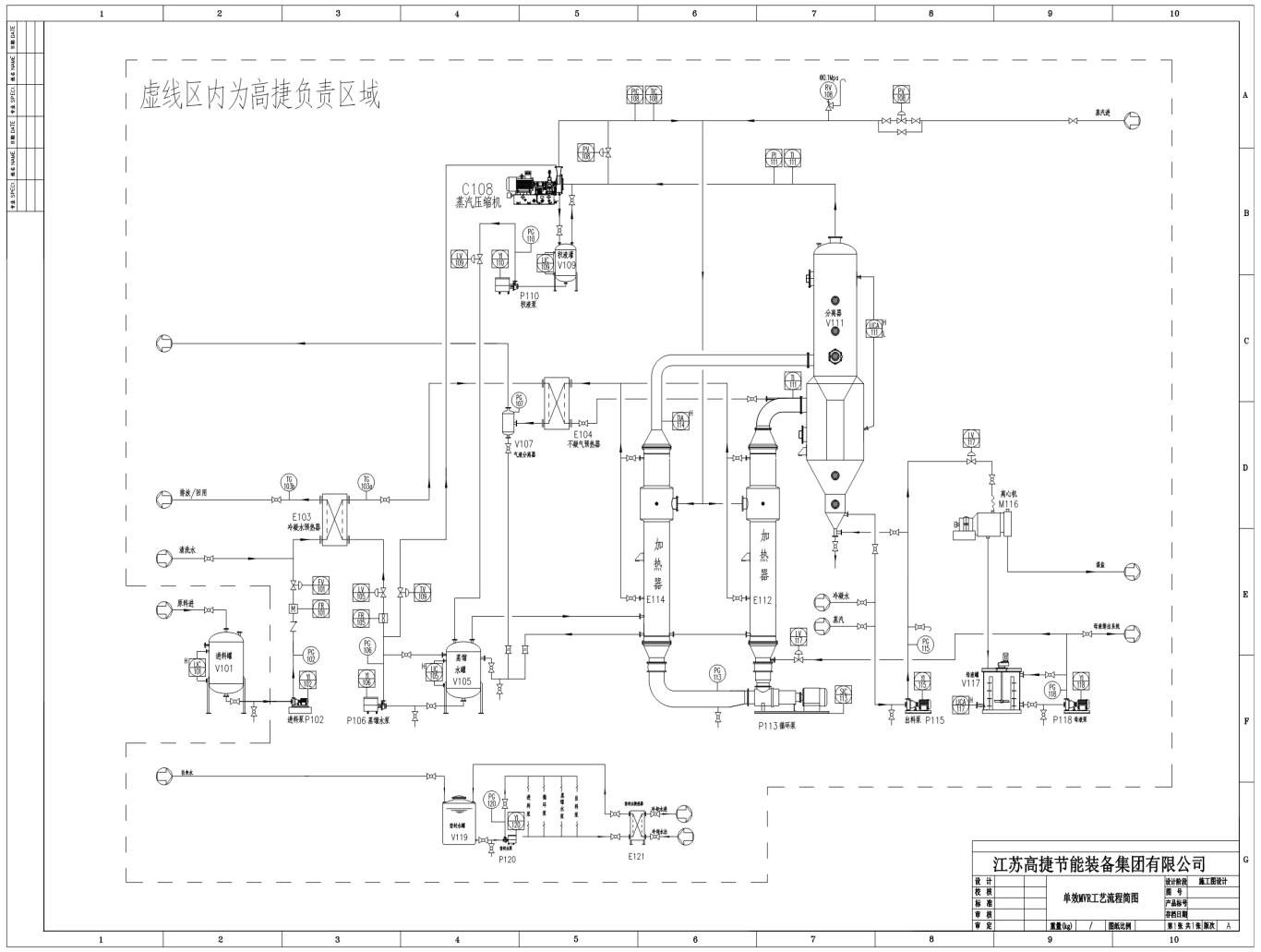

After passing through a distilled water preheater and a non-condensable gas preheater, the dilute zinc sulfate solution enters the MVR shell-and-tube forced circulation evaporation system for evaporation and crystallization. The crystal slurry is pumped to a centrifuge by a discharge pump, and the salt is discharged by centrifugation. The mother liquor is returned to the evaporation system, and the crystallized salt is handed over to the owner for processing.

The secondary steam generated by the evaporator is compressed by the compressor and used as the heat source for the evaporator. After being condensed, it is sent to the dilute zinc sulfate solution via a distillation water tank and a distillation water pump for preheating before being reused/discharged.

1.2.1Feed preheating unit

The feed preheating unit consists of a feed pump, a distilled water preheater, a non-condensable gas preheater, and related components. The material enters the evaporation system after passing through the feed pump and undergoing two stages of preheating. The first stage preheater is a distilled water preheater, where the evaporated water heats the raw material. The second stage preheater is a non-condensable gas preheater (because the raw material contains a small amount of non-condensable gas and the system operates under negative pressure, air may be mixed into the evaporation system. During evaporation, non-condensable gas gradually accumulates in the system, significantly reducing the evaporator's heat exchange efficiency. Therefore, it is necessary to remove the non-condensable gas, but the removed non-condensable gas will contain some water vapor. The purpose of the non-condensable gas preheater is to recover this carried-out water vapor to save energy). After preheating, the liquid reaches its bubble point and enters the evaporation unit.

1.2.2MVR Evaporator Unit

The evaporator crystallization unit is an MVR evaporation system consisting of a forced circulation heater, an OLSO crystallizer, a circulation pump, and a compressor.

The material enters the evaporator and then the circulating pump for heating. The gas phase separated in the separation chamber is compressed by the compressor and then used to heat the material in the circulating pipeline after the superheat is eliminated. The secondary steam, after releasing latent heat, turns from gas to liquid and is collected in the distilled water tank. Most of it is sent to preheat the raw materials by the distilled water pump, and a very small portion is sent to the compressor to eliminate the superheat of the steam.

Because the circulation flow rate within the heater tubes is very high, the material temperature rises only by 0.5–2°C after passing through the evaporator. No phase change occurs within the evaporator, and the material flows at high speed within the tubes, effectively preventing scaling within the heat exchange tubes—a forced circulation mechanism. The heated liquid then flashes in the separation chamber, and the resulting secondary steam is continuously heated and pressurized by the compressor to further heat the liquid, thus creating a continuous cycle. Therefore, the entire evaporation process only requires a small amount of fresh steam to maintain system heat loss and achieve equilibrium.

In forced circulation evaporation crystallization, controlling the appropriate supersaturation is crucial. Crystallized particles in the circulating liquid gradually grow, and the salt content in the salt leg can be observed through a sight glass. An OLSO crystallizer is used, which has the advantage of producing larger crystal particles. In the OLSO crystallizer, large crystal particles gradually sink due to gravity, while smaller crystal particles float. The liquid containing the small particles is then recirculated by the circulation pump. This allows newly formed crystals to grow directly on the surface of the existing small particles (i.e., secondary nucleation), thus resulting in larger crystal particles.

1.2.3Steam system

Apart from the need for a certain amount of live steam during system startup, the system requires only a small amount of live steam to compensate for heat loss and preheating during normal operation. The secondary steam generated by material evaporation enters the steam compressor, where it is heated and pressurized before returning to the heater shell, serving as the heat source for material evaporation.

1.2.4Condensate/Distilled Water System

After the secondary steam exchanges heat in the evaporator, it condenses and enters the distilled water tank. It is then pumped to the distilled water preheating material by the distilled water pump, and after heat exchange, it is sent out of the evaporation workshop.

1.2.5Discharge system

In the OLSO crystallizer, larger crystal particles sink and are pumped to a centrifuge. The purpose of the centrifuge is to separate the solid and liquid. The separated wet salt (water content <5%) is processed by the owner. The mother liquor after centrifugation enters the mother liquor tank and is mostly returned to the separator for further evaporation and crystallization by the mother liquor pump. A small portion is discharged from the system (or not discharged).

1.2.6exhaust unit

The exhaust unit consists of a non-condensable gas condenser, a separator, and related components. Due to the dissolved oxygen and non-volatile gases in the raw material, a small amount of non-condensable gas exists within the system. This gas cannot be condensed in the evaporator. If this gas is not discharged, the heater's heat exchange efficiency will be significantly reduced, the secondary gas pressure will increase, and consequently, the system's evaporation capacity will decrease, affecting normal system operation. Therefore, to ensure smooth evaporation, the non-condensable gas must be discharged from the shell side of the heat exchanger. After preheating the raw material in the non-condensable gas preheater, the non-condensable gas enters the exhaust system.

1.3Technical parameters

- Water evaporation rate: ~ 3600 kg/h

- Feed rate: ~5000 kg/h

- Feed temperature: 25 ~30℃

- Feed concentration: approximately 25 % zinc sulfate

- Steam consumption: ~200kg/h

- Circulating water volume: ~30m³/h

- Operating power: ~ 24.5 kW