Pre treatment sedimentation facilities (equipment) for water treatment

Water treatment pretreatment process

Coagulation sedimentation process

In the process of treating industrial water using coagulation, sedimentation, and filtration processes, the water purification facilities (equipment) used in different places are also different. The reaction facilities currently used include eddy current reaction tanks, perforated cyclone reaction tanks, mechanical stirring reaction tanks, magnetic separation technology and high-efficiency cyclone technology; sedimentation facilities include advection sedimentation tanks, inclined tube (inclined plate) sedimentation tanks and mixed High-density settling tanks, mechanically accelerated clarifiers, hydraulic circulation clarifiers, etc. that combine the coagulation reaction and sedimentation process; various treatment facilities have their own advantages and disadvantages.

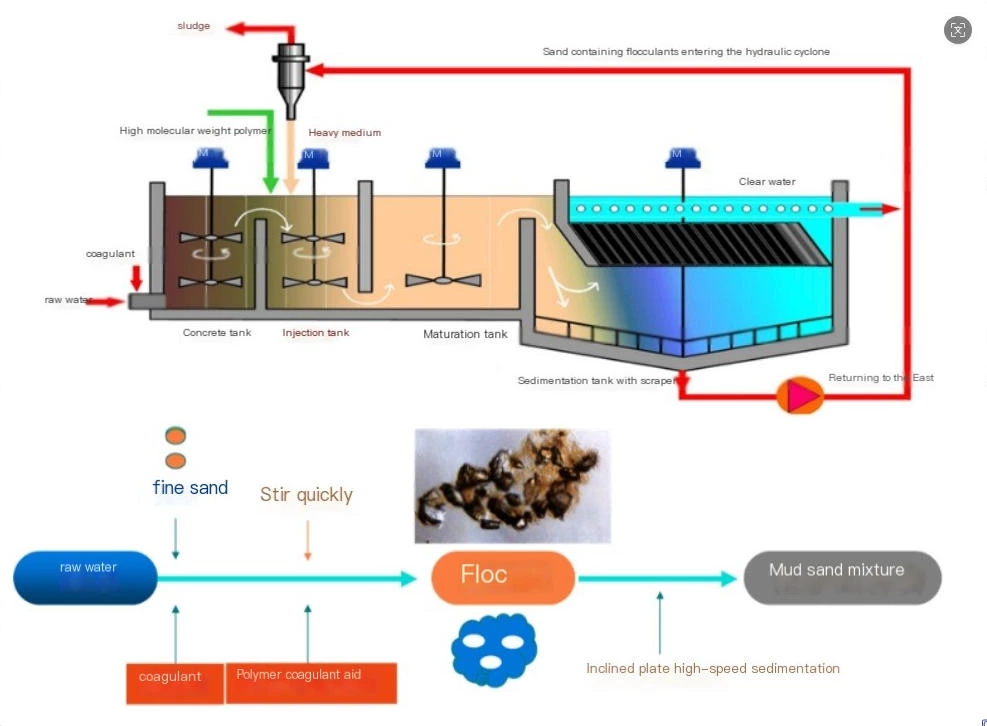

Schematic diagram of high-density sedimentation tank structure

In addition, in recent years, processes such as heavy medium velocity sedimentation, ultramagnetic separation and high-efficiency cyclone have also been applied in many projects in coal mine industrial water pretreatment projects. These emerging processes have the characteristics of relatively high equipment integration and large floor space. It has the advantages of being relatively small and having better water quality.

Principle diagram of heavy medium rapid sedimentation process

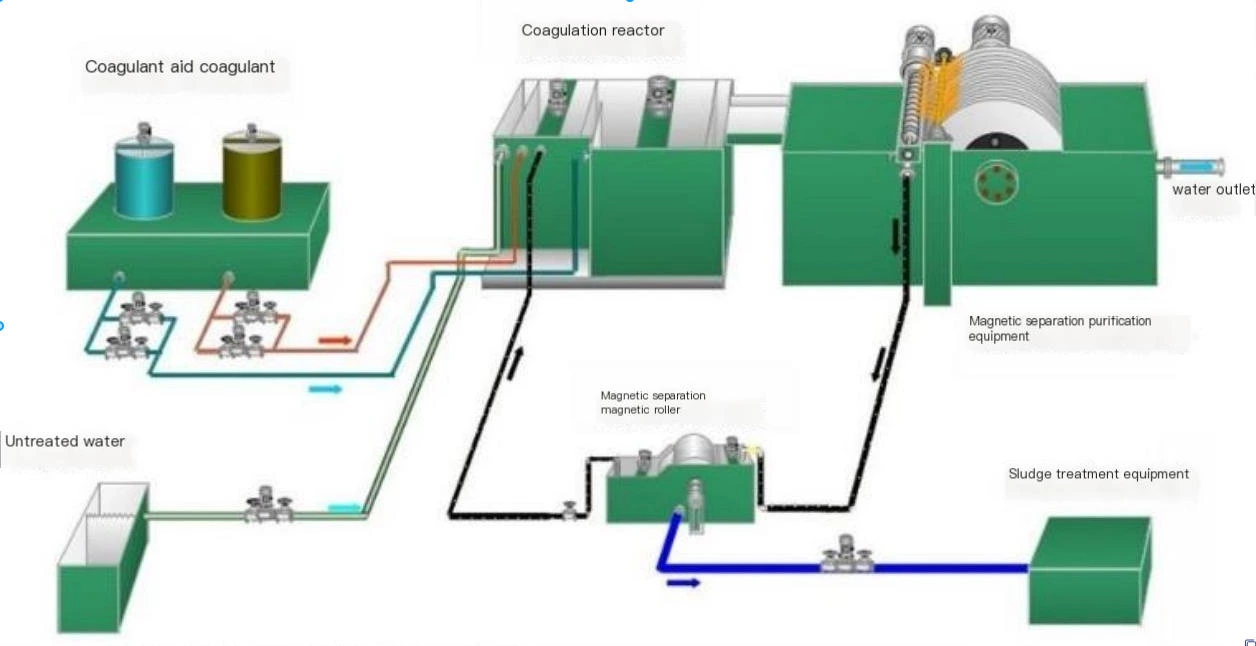

Re-mediated high-speed sinking (micro-sand cycle) equipment and super-magnetic separation technology are relatively similar to the two, are added to the raw water with a certain medium (re-mediated high-speed sinking is added to the activated sand, super-magnetic separation technology is added to the magnetic species), in the synergistic effect of the flocculant and coagulant aids to accelerate the separation of suspended solids in the water from the water and precipitate, suspended solids can be removed, and then follow up on the part of this medium from the precipitation of coal sludge to separate for Recycling.

Super Magnetic Separation Technology Schematic

High-efficiency cyclone purification process is the use of cyclone mixing, atmospheric cyclone, secondary cyclone centrifugal separation, turbulent particles sludge layer filtration, flow filtration principle of sewage purification of coagulation reaction, centrifugation, slurry layer filtration, dynamic filtration, sludge thickening, and other treatment technologies organically combined together, in the same tank for a short period of time, so that the water I suspended matter in the centrifugal action of rain sewage separation and thus achieve purification.

For the emerging technologies have the advantages of short purification time, small footprint, suitable for downhole arrangement, but heavy medium speed sinking (micro-sand circulation) technology, super-magnetic separation technology and high-efficiency cyclone technology to achieve relatively good results, it is understood that the need to add a large number of flocculants and coagulants to the water, the effluent water tends to leave a certain amount of flocculants, which will cause a certain degree of trouble to the subsequent depth of the membrane treatment treatment process.