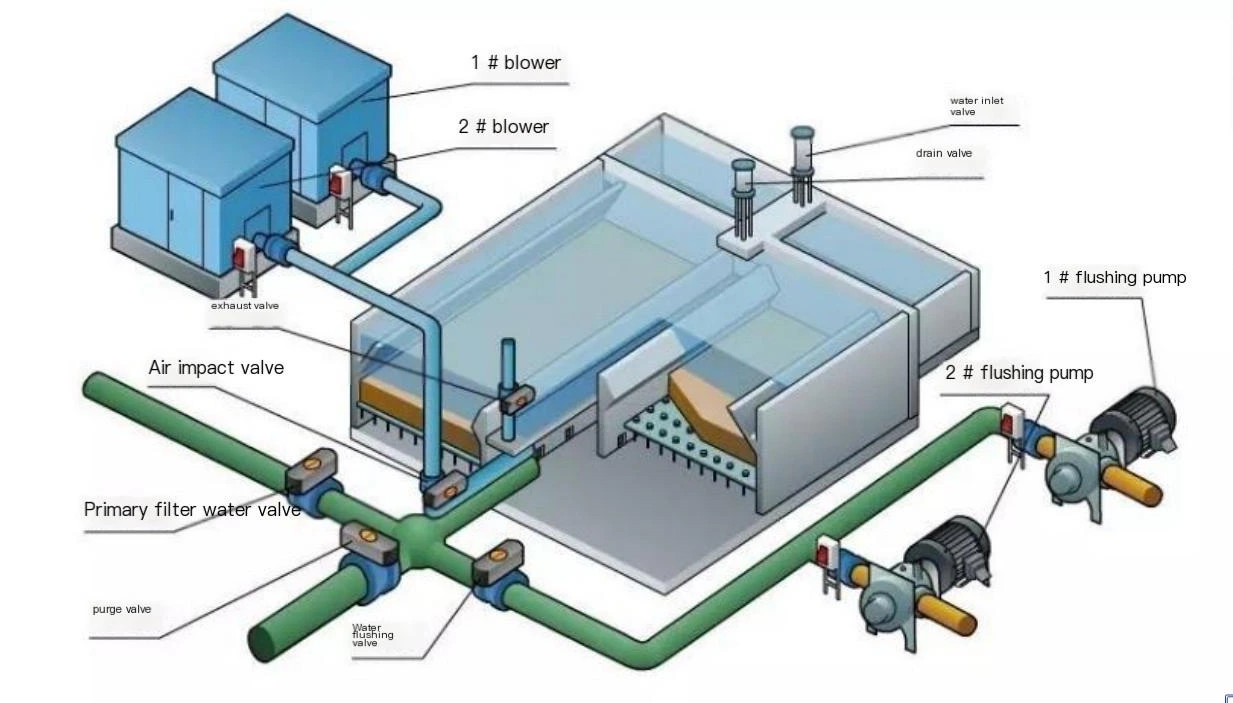

Pre treatment filtration facilities (equipment) for water treatment

Water treatment pretreatment process

Filtration process

Filtration is the main process link in the water purification process, and the filtration effect directly affects the quality of pretreated water. There are many types of filters, such as ordinary rapid filters, siphon filters, V-shaped filters and valveless filters. Ordinary rapid filter technology is relatively backward, and must have backwash equipment. The pipe gallery is also very large, and the filter water must be adjusted. Otherwise, the primary filtration speed is too fast and easy to penetrate because it is a variable speed filtration system; siphon filter, V-type filters are most suitable for large water plants, which can reduce the additional cost of equipment to the cost per ton of water. For small water plants, the cost is too high, management is complex, and it is not easy to afford; valveless filters do not require Personnel management, automatic operation after initial adjustment, no valve control required for water inlet, outlet, backwash water supply, and backwash wastewater removal.

Commonly used filtration forms in industrial water treatment processes include ordinary rapid filters, V-type filters, valveless filters, and filters.

Ordinary rapid filter refers to an ordinary four-valve rapid filter, which consists of the filter body, flushing facilities, pipe gallery and control room. It is widely used in water supply treatment. It has single and double layers of filter material and large resistance water distribution system. It has good flushing effect and strong dirt holding capacity. Its disadvantages are that there are many valves, complicated operation and management, and single water flushing, the flushing effect is not as good as the gas-water backwash filter.

The V-shaped filter is also called a uniform filter material filter. The V-shaped groove is arranged along the long side of the filter bed, which not only distributes water evenly, but the water inlet hole at the bottom can also function as a surface sweep during backwashing. Set up an outlet weir to ensure a constant water level after filtration, which is helpful in preventing negative pressure in the filter material layer; using uniform filter material, large waste interception capacity, long filtration cycle, good effluent water quality, and low backwash expansion rate of the filter material layer, sand runoff The possibility is small and the safety is high.

The operation process of the V-type filter is divided into two parts: filtration cycle and backwash cycle, which alternate with each other. After the filtered water passes from the main water inlet channel through the water inlet valve and two water windows (mainly used for surface rinsing), it overflows the weir and then enters the V-shaped groove through the side holes. It passes through the evenly distributed water distribution holes and V-shaped grooves at the bottom of the groove. The top of the trough weir enters the filter tank. The clean water filtered by the filter layer flows into the bottom of the filter tank through the filter head, flows into the gas and water distribution pipe channel through the water distribution window, and then flows into the clean water pool through the water sealing well, water outlet weir, and clear water channel in the pipe gallery.

Backwashing uses air flushing, air and water backwashing at the same time, and water flushing in three steps:

1) Close the water inlet and filtered water outlet valves, open the flushing and drainage valve, lower the liquid level in the filter tank to the top of the drainage tank; start the fan, open the air inlet valve, and the air will evenly enter the filter through the upper air distribution holes of the air and water distribution channel. The water and air distribution chamber at the bottom of the pool are sprayed from the long-handled filter head to scrub the impurities on the surface of the filter material and suspend them in the water.

2) Start the backwash pump and open the flush water valve. At this time, air and water enter the air and water distribution channel at the same time, and evenly enter the filter tank through the air distribution hole, water distribution square hole and long-handled filter head, so that the filter material can be further washed.

3) Stop air flushing and flush with water alone; about one minute before the end of backwashing, the pneumatic water inlet gate turns to a half-open state, sweeps the horizontal surface, and flushes all floating objects suspended on the water surface into the central drainage channel , collected into the backwash drainage channel, and finally led to the pretreatment regulating pool by the pipeline.

V-shaped filter structure diagram

Because the V-type filter adopts a coarser and thicker quartz sand filter layer with uniform particles; it uses air and water to backwash the filter layer at the same time without causing the filter layer to expand and sweep the surface of the water to be filtered; it uses an air cushion to distribute air and A special long-handled filter head is used for gas and water distribution and other processes. It has the characteristics of good water quality, fast filtration speed, long operation cycle, good backwash effect, energy saving and easy automatic management.

Valveless filters refer to filtration facilities with few control valves, automatic operation, no need for additional flushing pumps or water towers, and low infrastructure investment. It mainly automatically controls the generation and destruction of siphon through the pressure difference between inlet and outlet water to achieve automatic continuous operation. It is divided into two forms: gravity type and pressure type.

Whether it is a gravity valveless filter or a pressure valveless filter, its working principle is basically the same, and its characteristics are:

1) There are no valves for water inlet, outlet, backwash and drainage. The operation and backwashing process are all controlled automatically by hydraulics. It's not like siphon filter, double valve or single valve filter. A siphon needs to be used instead of a valve, and a set of vacuum equipment needs to be installed.

2) Variable water head and constant speed filtration. Changes in water head are reflected in changes in water level in the siphon. That is, as filtration progresses. The water level in the siphon gradually rises. Backwash until siphon is formed. throughout the filtration process. Keep equal amounts of water. That is, the water head changes, but the water volume remains unchanged.

3) The backwash water tank is located at the upper part of the filter, eliminating the need for a dedicated flushing water tank or flushing water pump. Reduced land occupation. Save electricity consumption. No running operation is required.

4) Low head backwash, small resistance water distribution system.

5) Operation and flushing are all automatically controlled by hydraulics, and no operation, management or maintenance is required. Just proper maintenance is required.

6) If the volume of treated water is relatively small, it can be made of steel plates. Transported to site for installation. Carry out equipment production. However, anti-corrosion treatment should be done.

In water treatment, it is often used in conjunction with a sedimentation tank (clarifier). The valveless filter uses a single layer of quartz sand filter material or a double layer of quartz sand and anthracite. It can more completely remove suspended solids and colloids in the water. Automatic backwashing, no need for external flushing pump or water tank, simple operation and management. However, the thickness of the filter material layer is thin, and the backwash intensity is difficult to adjust during automatic backwash. When there are more suspended solids or colloids trapped or the filter layer is seriously contaminated, the flushing effect is not good.

The filter is a kind of filter whose filter material uses quartz sand as filler. Helps remove impurities from water. It also has the advantages of small filtration resistance, large specific surface area, strong acid and alkali resistance, and good pollution resistance. The unique advantage of the sand filter is that it realizes the adaptive operation of the filter by optimizing the design of the filter material and filter. The filter material has strong adaptability to raw water concentration, operating conditions, pre-treatment processes, etc. That is, during filtration, the filter bed automatically forms an upper sparse and lower dense state, which is beneficial to ensuring the quality of the effluent water under various operating conditions. During backwashing The filter material is fully spread out and the cleaning effect is good. The sand filter can effectively remove suspended solids in the water, and has a significant removal effect on colloids, iron, organic matter, pesticides, manganese, bacteria, viruses and other pollutants in the water. It also has the advantages of fast filtration speed, high filtration precision, and large sewage interception capacity.

When the normal operation of the filter is affected by retaining excessive impurities, it can be cleaned by backwashing. Use reverse water inflow and compressed air at the same time to mix and scrub with air and water to loosen the sand filter layer in the filter. The trapped matter adhered to the surface of the quartz sand can be peeled off and taken away by the backwash flow, which is beneficial to the discharge of the filter. Sediment, suspended matter, etc. in the layer are removed, and the filter material is prevented from hardening, so that it can fully restore its interception capacity.