Zero discharge of high salt and organic wastewater

Typical treatment process: pre-treatment+evaporation+biological treatment+deep treatment

Pretreatment: mainly including soften reaction tank, coagulation sedimentation tank, etc

Evaporation: including multi effect evaporation, MVR, etc

Biological treatment: mainly using membrane bioreactor (MBR)

Advanced treatment: membrane process(NF,RO),non membrane process such as "secondary fenton oxidation+biological treatment" have also begun to be used in engineering

The incoming water with high organics and TDS. High TDS (>20000ppm)cann’t degrade COD by biological treatment. The process is mainly biochemical after desalting, and the final product is the qualified water, biochemical sludge and mixed salt.

Pretreatment process

High density sedimentation tank

- adjust pH;

- Removing alkalinity and hardness ions by adding chemicals;

- Dosing to remove suspended solids

V filter

- Filter to remove suspended solids;

- Automatic operation, adaptable to fluctuations in water quality and quantity;

- Large treatment water.

Biological treatment

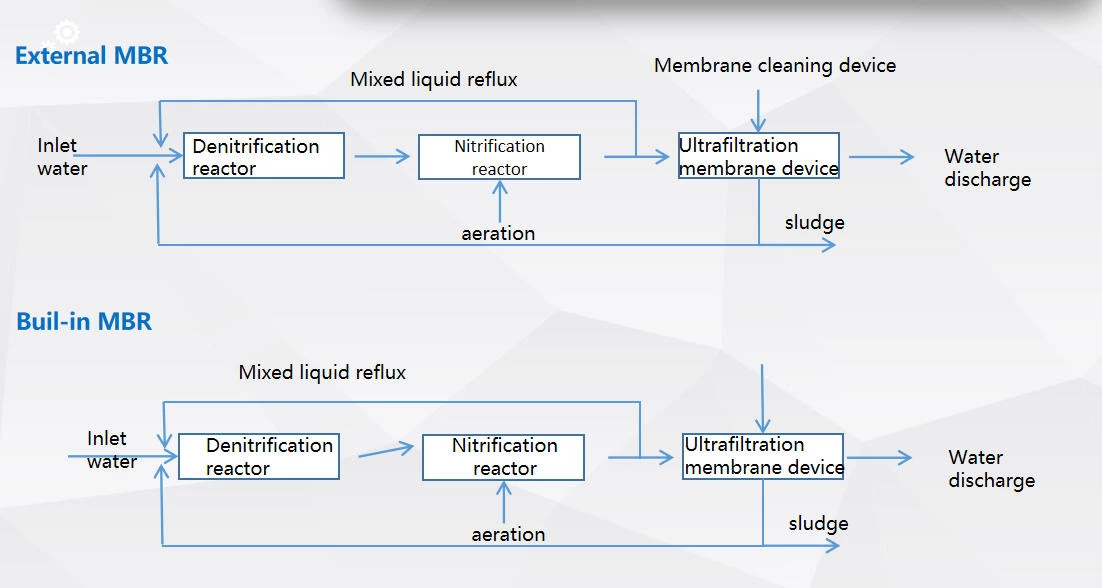

Membrane bioreactor(MBR)

Inlet water pollutant indicators:

- COD:≤20000mg/L

- BOD5/COD:≥0.3

- NH3-N: ≤ 2500mg/L

- BOD5/NH3-N: ≥ 5

Advanced Treatment

Nanofiltration(NF) and Reverse osmosis(RO)

Inlet water pollutant indicators for NF process

- COD: ≤1200mg/L

- BOD5: ≤ 30mg/L

- Oxidation-reduction potential (ORP):<200mg/L

- Inlet water pH: < 7

Inlet water pollutant indicators for RO process

- COD:Roll RO ≤ 1000mg/L,DTRO≤10000mg/L

- Oxidation-reduction potential (ORP): < 200mg/L

- Max inlet SDI15:Roll RO < 5,DTRO < 6.5

- NH3-N :Roll RO<50mg/L,DTRO < 800mg/L;

- Inlet water pH: < 7

Disc tube reverse osmosis(DTRO)

- Separate concentrated solution and permeate solution O-ring

- Low pre-treatment requirements and strong pollution resistance

- Effectively avoiding membrane blockage and concentration polarization phenomenon