Evaporation and crystallization of calcium chloride solution

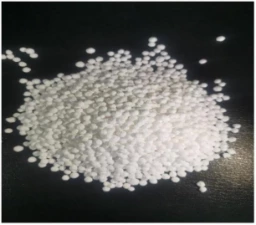

Calcium chloride (chemical formula: CaCl2) is a white or slightly yellowish solid inorganic compound belonging to the salts group, which are typical ionic halides widely used in a number of fields due to their high solubility, hygroscopicity and dehydrating properties. Depending on its hydrated form it exists in different physical forms, the most common being calcium chloride dihydrate, whose high solubility allows it to dissolve rapidly in water, releasing a large amount of heat and thus making it very useful in applications that require rapid heating or drying. In addition, calcium chloride is often used in applications including brines for refrigeration equipment, road ice melt and desiccants.

Calcium chloride solution evaporation crystallization generally has two forms, output anhydrous calcium chloride or calcium chloride dihydrate. Calcium chloride solution is characterized by large solubility, elevated boiling point and strong corrosiveness, and in evaporation crystallization, it needs to consume a large amount of energy, and the material is chosen as TA2/TA10/TA9.

The process of producing anhydrous calcium chloride by using evaporator is as follows: use MVR to evaporate and concentrate up to 35%, then use multi-effect evaporator to concentrate up to about 45% concentration, and finally pump to spray drying and granulation to produce anhydrous calcium chloride. Requirements for public works: power supply, steam, natural gas.

The process of producing calcium chloride dihydrate by evaporator is as follows: using MVR evaporation and concentration to 35%, then using multi-effect evaporator to concentrate to about 45% concentration, and finally using single-effect evaporator to concentrate to 68% concentration to go to slicing machine, and produce calcium chloride dihydrate. Public works requirements: power supply, steam.