Plate heat exchanger in sulfuric acid application

Heat exchangers are often used in the preparation and transportation of sulfuric acid. The most common is the sulphuric acid cooler, where the hot side is the sulphuric acid solution, with a concentration ranging from 1% to 98%, and the cold side is the circulating water.

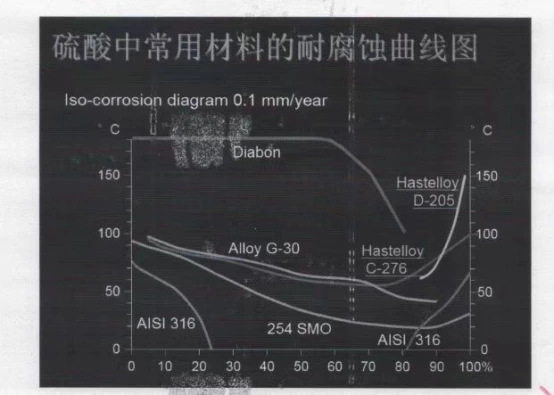

Considering that sulfuric acid is highly corrosive and leakage is hazardous, it is recommended to use welded seals on the sulfuric acid side and choose corrosion-resistant materials.The corrosion resistance curve of commonly used materials in sulfuric acid is shown in the figure below. At present, the main optional materials for sulfuric acid are C276, D205, ALLoy G-30, SMO254, 904L, 316L, etc. The specific material needs to be selected according to the concentration and temperature of sulfuric acid. Specific materials need to be selected according to the concentration and temperature of sulfuric acid.

Currently in the sulfuric acid industry, plate heat exchanger usage is steadily increasing, ordinary plate heat exchanger relies on rubber gasket sealing, due to the rubber product is easy to aging, easy to expansion, so the leakage rate is higher, in order to ensure production safety, our company recommends the use of semi-welded plate heat exchanger.

Semi-welded plate heat exchanger, two plates welded to form a group, after welding the two plates formed by the welded channel to go sulfuric acid solution, plate group and the channel formed between the plate group sealed with a rubber gasket, used to go to the circulating cooling water. This heat exchanger cost is lower, while the circulating water scaling, you can dismantle the plate heat exchanger for cleaning, to ensure the flexibility of the plate heat exchanger.